|

Zhoushan Weida Machinery Co., Ltd.

|

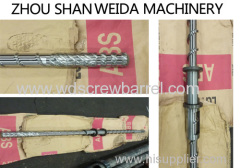

screw and barrel for PE

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

PE Production Extruder Screw barrel for PE

Steel Material:38CrMoALA,SKD61,SKD11,D2 etc.

Hardness after Hardening & Tempering:HB240-280

PE Production Extruder Screw barrel

Specification of injection screw barrel:

For screw: Dia. 15-300 mm Length 300-9000 mm L/D ratio: 15-50

For barrel: Dia. 30-500 mm Length 300-8000 mm

Specification of injection screw barrel:

For screw: Dia. 15-300 mm Length 300-9000 mm L/D ratio: 15-50

For barrel: Dia. 30-500 mm Length 300-8000 mm

Steel Material:38CrMoALA,SKD61,SKD11,D2 etc.

Hardness after Hardening & Tempering:HB240-280

Working Process :

Raw Material → Quenching & Tempering → Rough Machining → Semi finish Machining → Finish Machining → Nitriding Treatment → Bimetallic Casting → Inspection → Finish Products

Technical Index

Steel Material | 38CrMoALA,SKD61,SKD11,D2 etc. |

Hardness after Hardening & Tempering | HB240-280 |

Nitriding Treatment Time | ≥ 96 hours |

Nitrided Layer Hardness | 950-1020Hv |

Nitrided Layer Thickness | 0.5-0.8mm |

Surface Roughness Degree | Ra0.4um |

Surface Hardness Degree | 58-64 HRC |

Screw Straightness Degree | 0.015mm |

Chromium-Plated Surface Hardness After Nitriding | ≥ 900HB |

Chromium-Plating Layer Thickness | 0.05-0.10mm |

Bimetallic Layer Hardness | 50-65HRC |

Depth Of Alloy Layer | 0.8-2.0mm |

Grade List

Grade | Steel Material | Processing |

Standard Grade | 38CrMoALA | Nitriding 96 Hours |

Bimetallic Grade | 38CrMoALA | HP/HVOF Spraying |

TC-A Grade | Tungsten Carbide40% | Centrifugal Casting |

TC-B Grade | Tungsten Carbide25% | Centrifugal Casting |

TC-C Grade | Tungsten Carbide10% | Centrifugal Casting |

Material Available

Nitrided Steel | 42CrMo,38CrMoALA,etc. |

Cool Work Steel | D2,SKD61,9Cr18MoV etc. |

Heat Resistant Steel | SKH51, GH113 etc. |

PE Production Extruder Screw barrel

1.rich strength----We have our own professional teams in the sales, design, production, inspection and customer service areas. We concentrate to bring customers the most perfect customer experiences.

2.high-quality products----We adopt a series of advanced production and processing equipments such as CNC machines , Stellite PTA welding machines to ensure the quality of our products

PE Production Extruder Screw barrel

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Screw Barrel

Screw And Barrel

Feed Screw Barrel

Twin Screw Barrel

Single Screw Barrel

Plastic Screw Barrel

More>>